Welcome to the Smart Home Founders series, where the people shaping today’s smart homes share their stories. In this edition, we talk to Trevor Schirmer and Justin Bunton, the founding duo of Apollo Automation, a promising smart home startup based in the US.

Apollo Automation is a hardware and software tech startup from Kentucky, US, focused on developing advanced multi-sensor devices and other innovative solutions for the smart home market. Founded in late 2023, the company has already successfully launched several smart devices and built a strong following among home automation fans, tinkerers, and DIY enthusiasts.

Hello Trevor and Justin! Thanks for joining me for our latest edition of the Smart Home Founders series. Can we start by sharing the origin story of Apollo Automation? How did you come around to forming a startup smart home company?

TREVOR: “Apollo really started like a simple weekend project. Justin and I are long-time home automation users, and we wanted a motion sensor that would combine a few other things as well. We were tired of buying separate devices for motion, temperature, or measuring light level. So, as a small project, we decided to combine it all into our first multi-sensor, the MSR-1. We posted it online, and it created a lot of noise, with people saying, “Hey, I would buy that.”

“We simply created a website and launched Apollo Automation. At first, we would get together one Saturday every month to assemble the devices in my basement. Then it became two Saturdays, then four, until we finally started working full time. We recognized there is a business here and started thinking about other sensors and building a community on Discord. We are having a blast along the way!”

JUSTIN: “Trevor always leaves out the best part. We had a running joke that our goal was to sell a couple of hundred sensors and buy a boat. That was the plan: cover our R&D costs and buy a boat to go wakeboarding!”

It’s always great to have goals! Many in the community fondly remember your first logo, which featured a distinct German Shepherd. There’s often a great story behind such a personal brand mark. Can you share the inspiration behind featuring a dog and what prompted you to change it to your current logo?

TREVOR: “My German Shepherd is named Apollo. We were playing lacrosse in the backyard one day, and we thought Apollo Automation sounded really nice, so we named it after him. We made this cartoon logo for our brand, which we thought was awesome!”

“But, as we started to grow, people thought we were a dog company, a pet brand. We joked for a while that we would make a smart sensor that you would attach to your dog’s tail so it would count the wags per minute and tell you how happy your dog is! Eventually, we ended up getting our logo redesigned by a professional.”

“However, we didn’t completely remove Apollo. We still hide him on our PCBs and inside the boxes. If you look closely, you will see our new logo is also a German Shepherd, just a minimalistic version with the dog looking sideways.”

Apollo Automation offers a range of multi-sensors, including presence, soil, and air quality sensors. How did you decide on this product lineup, and what specific needs in the smart home market were you aiming to address?

JUSTIN: “We have a future product survey that drives our R&D decision making. We do not want to enter the market with a product that isn’t innovative or competitive. We spend a lot of our time thinking about this.”

“Like Trevor said, when we started the company, there wasn’t a millimeter wave sensor that was a multi-sensor. Something that could also do temperature, humidity, UV, have addressable LEDs, or a piezo buzzer. When we released the MSR-1, there were a lot of positive reactions on Reddit, Facebook, and community forums, and we just continued with that model of multi-sensors. We look at what people want and need and try to deliver.”

Do you have a product that you consider your “hero product” out of your current range of sensors and devices?

TREVOR: “The MSR-2 and the AIR-1 are our two most popular devices. The MSR-2 is a millimeter wave multi-sensor that also measures temperature, humidity, illuminance, air pressure, UV index, and CO2.”

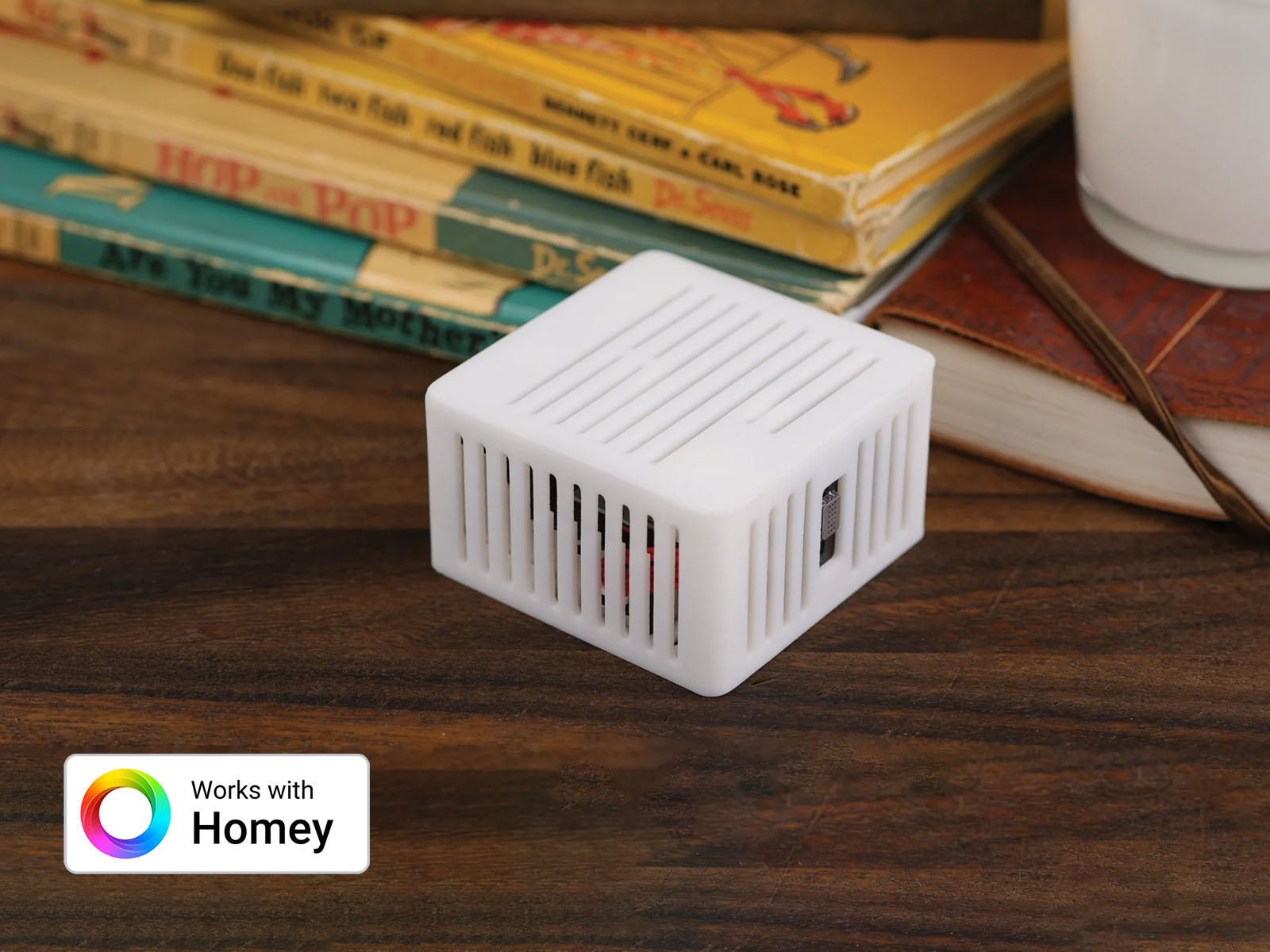

“The AIR-1 is a complete indoor air quality monitor, measuring CO2, CO, PM, VOC, NOx, temperature, humidity, air pressure, and gases like Alcohol (C2H5OH), H2, NO2, and NH3. The MSR-2 is equipped with a piezo buzzer, which can be used for audible notifications and alerts. At the same time, both the MSR-2 and the AIR-1 feature our trademark addressable LED, which doubles as a visual indicator.”

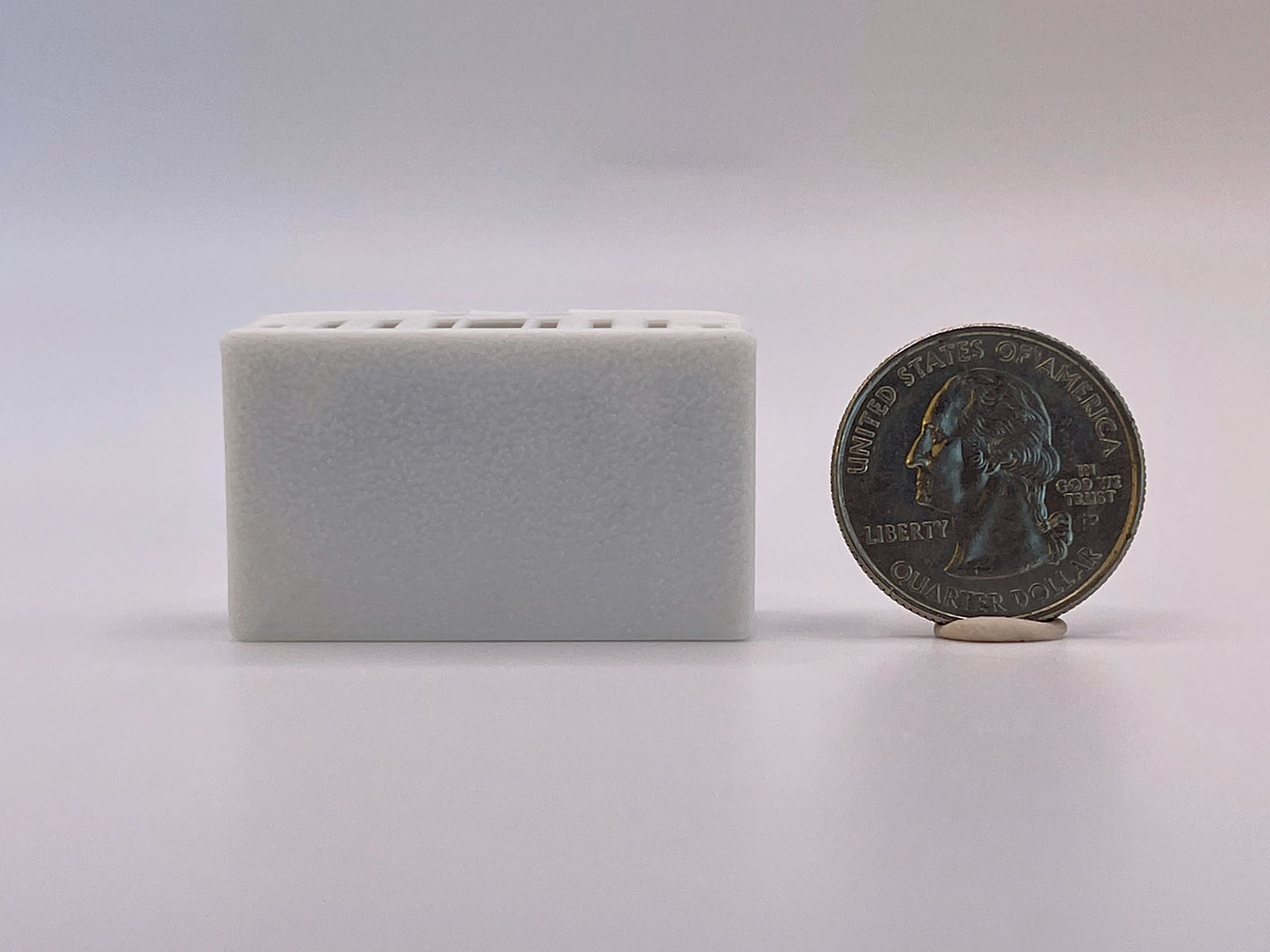

Your sensors are known for their remarkably small size. What were the key design and engineering challenges in achieving this compact form factor, and why was it such a priority?

TREVOR: “Indeed, making a very small multi-sensor is much more challenging than a large one. As devices like motion and air quality sensors are installed throughout your home, they are usually very visible. The smaller we can make them, the better they can fit in your environment and not be an eyesore.”

“It poses a significant challenge fitting so many components and features together. Because we do all our designs in-house, combining everything, reducing the size, and managing heat generation inside the case is particularly challenging. Sometimes I think, why do we torture ourselves to make this so small?”

JUSTIN: “The minuscule size is part of the brand now, so we don’t have a choice anymore.”

Can you walk us through the manufacturing process for your sensors? Where are the devices made, and how does the assembly process work?

TREVOR: “When Justin and I started the company, we really wanted to grow jobs in our local community. Because we do all of our R&D, engineering, and design in-house, that was very important to us. All of our PCBs are manufactured overseas, but then sent back to us. We test, flash, assemble, put them in cases, box, and ship them all out from here in Kentucky, which is kind of in the middle of the US.”

“This gives us huge control over the process. We did some tests with contract manufacturing, but the time it takes to go back and forth to fix simple issues wasn’t worth it for us. This way, we can redesign the case in the morning and have our people assemble the devices with the new case by the end of the day.”

As Apollo Automation has grown, how has your team structure evolved? Could you give us an idea of the current team size and perhaps touch upon the company’s key roles or focus areas?

TREVOR: “It’s been a blast trying to grow a small company. But, as we’ve been growing, we realized it was becoming too much to manage on our own. First, we hired Brandon as a support tech, who has given us phenomenal support in this industry. If you reach out to us on Discord or our website, you’re talking to Brandon pretty much right away.”

“Next, we hired Justin’s sister as our fulfillment officer. She ships our products and takes care of our customers every day. Then our friend Kyle came on board as an operations manager. He manages procurement of new parts, oversees fulfillment, and runs day-to-day operations. This has allowed Justin and me to focus on product development and growing our brand.”

You have a strong integration with Homey through the Apollo Automation App. What was the development process like working with the Homey team, and how do you see the relationship evolving to benefit the user?

TREVOR: “The Homey team is awesome! They connected us with the right people and gave us every resource to develop the app properly. It was great meeting them at CES, which really helped us kick off on a good foot. They move quickly, and we are now officially selling Homey Pro on our website here in the US! We frequently do giveaways in our local community, and Homey has been a part of that. Whenever we reached out for a giveaway, they were always like, “Hey, we’ll throw in a Homey with that!”

JUSTIN: “I think the Homey Pro mini will definitely be a hit. The price is right for the market here, and there has been a great response from our network of testers and influencers.”

What is your perspective on the current state of the smart home market? Do you see Matter as a big opportunity for Apollo Automation?

TREVOR: “I think the market is just booming. More and more people are getting into home automation, and even companies like hotels, apartment complexes, or resorts are starting to use smart devices. I also appreciate that people increasingly want local control over their smart home devices. This alone is a huge opportunity for Apollo Automation.”

“I like the direction Matter is heading, but I still believe it has a long way to go. It works really well for simple devices and single sensors, but for our products, where we have six or seven sensors in a single device, Matter just doesn’t work at the moment; it’s not there yet.”

JUSTIN: “We’re also exploring Zigbee as a potential communication protocol for our devices. Using Zigbee is actually the biggest request we get from the community. We are in the process of developing all our boards with the new C6 chip, which supports Matter, Thread, Zigbee, and Wi-Fi.”

What’s next for the company in terms of new products? Can you give us a sneak peek at what you’re working on? Are you making any changes to your production process?

JUSTIN: “We’ve finally moved out of Trevor’s basement, so at least our moms are proud of us now (laughs). We have our own building and it’s been great fun setting everything up. We just got a robot arm that we’re going to be using to flash PCBs for us. That was one of the biggest time sinks for the company, and now it’s automated.”

“We are also switching to resin printing our cases. We wanted to do injection molding, but we found resin to be a better match for us. It gives us the premium quality like injection molding, but it also allows us to make changes quickly based on community feedback.”

TREVOR: “We also have a couple of new products coming up. We are releasing a new PoE (Power-over-Ethernet) mmWave multi-sensor. It actually combines two separate radar sensors to provide reliable static presence detection and multi-target zone tracking in one device. You can mount it on the ceiling or wall or install it in a switchbox.”

“We are also developing a garage parking sensor. It will tell you how far away you are from the wall, if you’re properly parked in your spot, and simply detect whether your car is there.”

Thanks for joining me today, guys. Before I let you go, can you share one piece of advice you would give aspiring smart home startups? What is something you wish you knew when you were just starting out?

TREVOR: “My number one advice is to get your product into people’s hands early. You don’t need to have this polished product that takes two years to make, that you develop in a sealed-off environment, before you give it to people. Get it into people’s hands as early as possible, so they can start testing and giving you feedback.”

JUSTIN: “I would say, don’t be afraid to fail, and fail often. And not all advice is good advice. We get some people telling us not to make our devices open source, to make them closed, and to make more money. But, we believe the open source community is much more responsive and provides invaluable feedback to an open-source project like Apollo Automation.”